Power Tool Used C170 Cobalt Base Alloy Stellite 12 Wood Working Saw Tips

Product Description

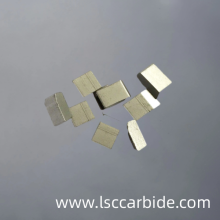

Product Introduction High precision Stellite 12 Cobalt chromium alloy saw tips Saw Blade For Cutting Wood Cobalt Chrome Alloy Stellite 12 Saw tips advantages (1). Stellite Alloy 12 could be considered an intermediate alloy . (2). It contains a higher fraction of hard, brittle carbides than Stellite Alloy 6 (3).It has increased resistance to low angle erosion, abrasion, and severe sliding wear while stretaining reasonable impact and cavitation resistance. (4). Stellite Alloy 12 is often used self-mated or running against . What is the Details of our stellite saw tips ?

Product Introduction High precision Stellite 12 Cobalt chromium alloy saw tips Saw Blade For Cutting Wood Cobalt Chrome Alloy Stellite 12 Saw tips advantages (1). Stellite Alloy 12 could be considered an intermediate alloy . (2). It contains a higher fraction of hard, brittle carbides than Stellite Alloy 6 (3).It has increased resistance to low angle erosion, abrasion, and severe sliding wear while stretaining reasonable impact and cavitation resistance. (4). Stellite Alloy 12 is often used self-mated or running against . What is the Details of our stellite saw tips ? | Material : | Stellite Alloy 12 |

| Process : | Powder Metallurgy , it is short for PM |

| Hardness: | 44-49HRC |

| Density : | 8.5g/cm ³ |

| Size : | Triangle , rectangle and profiled , customized-made is also available |

| Properties : | Wear and corrosion resistance |

| Application : | Cobalt Chrome Alloy is also more resistant to the abrasive acids found in some woods like red cedar. |

| Instructions : | The Cobalt Chrome Alloy Tipped saws, have a tip welded directly to the saw tooth |

| Usage : | Welding on Circular saw and Band saws teeth to cut woods |

| Tolerance control : | Surface polishing and tolerance ±0.003”/±0.005” (±0.0762/±0.127mm ) |

| Production lead time | Samples 7 days , normal order 10-25 days |

| Production capacity : | 1000,000pcs one month. |

| Package : | 1000pcs in 1 plastic bag and put in 1 plastic keg |

Related Products

Related Products

Q1: Are you a manufacturer or a trading company? A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience. Q2: What's the material of your bushings/sleeves? A2: It's the CoCrW alloy, which is usually called stellite alloy. Q3: What's the stellite alloy? A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat resistance and corrosion resistance. Q4: What's the lead time of extrusion mould? A4: 15-35 days depending on the order quantity. Q5: What's the tolerance and surface finish we can control? A5: As your demand. Q6: How do we deliver the seats? A6: We are the VIP customer of DHL express with good discounts. Q7: MOQ? A7: 500pcs Q8: Why I choose your company? A8: We are professional. We are reliable. We are easy communication. Your feedback is our best honor, please do not hesitate to give us your valuable feedback. Send your inquiry details in the below for free sample , Click "Send" Now ! Contact us if you need more details on Saw Tips. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Working Saw Tips、Stellite 12. If these products fail to match your need, please contact us and we would like to provide relevant information.

Q1: Are you a manufacturer or a trading company? A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience. Q2: What's the material of your bushings/sleeves? A2: It's the CoCrW alloy, which is usually called stellite alloy. Q3: What's the stellite alloy? A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat resistance and corrosion resistance. Q4: What's the lead time of extrusion mould? A4: 15-35 days depending on the order quantity. Q5: What's the tolerance and surface finish we can control? A5: As your demand. Q6: How do we deliver the seats? A6: We are the VIP customer of DHL express with good discounts. Q7: MOQ? A7: 500pcs Q8: Why I choose your company? A8: We are professional. We are reliable. We are easy communication. Your feedback is our best honor, please do not hesitate to give us your valuable feedback. Send your inquiry details in the below for free sample , Click "Send" Now ! Contact us if you need more details on Saw Tips. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Wood Working Saw Tips、Stellite 12. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : saw tips

Premium Related Products