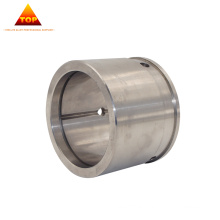

Heavy Duty Hydraulic Cylinders

Basic Info

Model No.: CD_CG250/CD_CG350

Product Description

Technical characteristics

- The dynamic seal adopts the v-ring group suitable for high speed and high pressure or the sliding ring combination with low friction coefficient suitable for low speed and low pressure

- The Hydraulic Cylinder is of double-acting single piston type, including differential cylinder and equal speed cylinder, with adjustable buffer (adjustable throttle valve is adopted).

Steel, casting, forging and machinery manufacturing industries such as harsh environment, heavy duty working conditions.

MODEL INSTRUCTION □□ □□□ □ □ /□ -□ □ 10 /□ □ □ □ □ □ * Hydraulic cylinder type series Installation form Bore mm Rod diameter mm Stroke mm Cylinder head and bottom connection Design Number Port connection method Piston rod material Piston rod thread End buffer Hydraulic medium Sealing structure Further explanation CD-Differential 250-25MPa A-Cylinder liner bushing earrings A- Both ends are threaded 01-Inch BS cylinder C-CK45, hard chrome plated surface G- suitable for earrings GA, U-无 M- mineral oil, T-slip ring combination seal CG-Constant velocity 350-35MPa B-cylinder bottom ball hinge earrings B-cylinder head is threaded, Pipe thread H-CK53, surface hardened, Thread GAK and SA, D-有 Nitrile rubber seal A-V seal C-cylinder head flange Cylinder bottom welding, suitable for live 02-Metric pipe thread Hard chrome plating, only applicable A-for GAS earrings V- phosphate, D-cylinder bottom flange Plug diameter ≤100mm Piston rod is less than 100mm Thread Adopt fluoro rubber seal E-Intermediate Trunnion Installation L-X22CrNi11. Surface F-base mounting Hard chrome plating SPECIFICATION CD 250/ CG 250 pressure piston mm 40 50 63 80 100 125 140 MPa diameter Piston rod mm 20 28 28 36 36 45 45 56 56 70 70 90 90 100 diameter 5 thrust KN 6.28 9.82 15.58 25.13 39.27 61.35 76.95 thrust 4.71 3.2 6.74 4.73 10.5 7.63 17.18 12.82 26.95 20.03 42.1 29.55 45.15 37.7 10 thrust 12.56 19.64 31.17 50.27 78.54 122.7 153.9 thrust 9.42 6.4 13.48 9.46 21 15.26 34.36 25.64 53.9 40.06 84.2 59.1 90.3 75.4 15 thrust 18.84 29.46 46.75 75.4 117.81 184.05 230.85 thrust 14.13 9.6 20.22 14.19 31.5 22.89 51.54 38.46 80.85 60.09 126.3 88.65 135.45 113.1 20 thrust 25.12 39.28 62.34 100.54 157.08 245.4 307.8 pull 18.84 12.8 26.96 18.92 42 30.52 68.72 51.28 107.8 80.12 163.4 118.2 180.6 150.8 25 thrust 31.4 49.1 77.9 125.65 196.35 306.75 384.75 pull 23.55 16 33.7 23.65 52.5 38.15 85.9 64.1 134.75 100.15 210.5 147.75 225.75 188.4 pressure piston mm 160 180 200 220 250 280 320 MPa diameter Piston rod mm 100 110 110 125 125 140 140 160 160 180 180 200 200 220 diameter 5 thrust KN 100.5 127.23 157.05 190 245.4 307.8 402.1 pull 61.25 53 79.7 65.87 95.7 80.1 113 89.53 144.9 118.2 180.6 150.8 245 212 10 thrust 201 254.47 314.1 380.1 490.87 615.75 804.25 pull 122.5 106 159.4 131.75 191.4 160.2 226.2 179 239.8 236.4 361.3 301.6 490 424 15 thrust 301.5 381.7 471.15 570.2 736.3 923.63 1206.4 pull 183.75 159 239.1 197.6 287.1 240.3 339 268.6 434.7 354.6 541.9 425.4 735.1 636.2 20 thrust 402 508.94 628.2 760.26 918.7 1231.5 1608.5 pull 245 212 318.86 263.5 382.8 320.4 452.38 358.14 579.6 472.8 722.56 603.2 980.2 849.2 25 thrust 502.5 636.17 785.25 950.33 1227.2 1539.4 2010 pull 306.25 265 398.57 329.37 478.5 400.5 565.47 447.6 724.5 591 903.2 754 1225.2 1060.3 CD 350/ CG 350 pressure piston mm 40 50 63 80 100 125 140 MPa diameter Piston rod mm 28 36 45 56 70 90 100 diameter 5 thrust KN 6.28 9.82 15.58 25.13 39.27 61.35 76.95 pull 3.2 4.73 7.63 12.82 20.03 29.55 37.7 10 thrust 12.56 19.64 31.17 50.27 78.54 122.7 153.9 pull 6.4 9.46 15.26 25.64 40.06 59.1 75.4 15 thrust 18.84 29.46 46.75 75.4 117.81 184.05 230.85 pull 9.6 14.19 22.89 38.46 60.09 88.65 113.1 20 thrust 25.12 39.28 62.34 100.54 157.08 245.4 307.8 pull 12.8 18.92 30.52 51.28 80.12 118.2 150.8 25 thrust 31.4 49.1 77.9 125.65 196.35 306.75 384.75 pull 16 23.65 38.15 64.1 100.15 147.75 188.4 30 thrust 37.69 58.9 93.5 150.8 235.6 368.1 461.7 pull 19.2 28.35 45.8 76.9 120.2 177.3 226.2 35 thrust 43.58 68.72 109.1 175.9 274.9 429.5 538.7 pull 22.4 33.07 53.4 89.7 140.2 206.9 263.9 pressure piston mm 160 180 200 220 250 280 320 MPa diameter Piston rod diameter mm 110 125 140 160 180 200 220 5 thrust KN 100.5 127.23 157.05 190 245.4 307.8 402.1 pull 53 65.87 80.1 89.53 118.2 150.8 212 10 thrust 201 254.47 314.1 380.1 490.87 615.75 804.25 pull 106 131.75 160.2 179 236.4 301.6 424 15 thrust 301.5 381.7 471.15 570.2 736.3 923.63 1206.4 pull 159 197.6 240.3 268.6 354.6 425.4 636.2 20 thrust 402 508.94 628.2 760.26 918.7 1231.5 1608.5 pull 212 263.5 320.4 358.14 472.8 603.2 849.2 25 thrust 502.5 636.17 785.25 950.33 1227.2 1539.4 2010 pull 265 329.37 400.5 447.6 591 754 1060.3 30 thrust 603 763.4 942 1140 1470 1847.3 2412.7 pull 318 395.1 480.06 537 703 904.77 1270 35 thrust 703.5 890.6 1099 1330 1715 2155 2814.8 pull 371 460.9 560.7 626.5 826 1056 1484

Product Categories : Hydraulic Valve > Oil Research Series