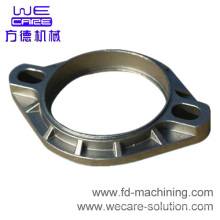

OEM Bucket Tooth Casting, Investment Casting, Lost Wax Casting

Basic Info

Model No.: IC-106

Product Description

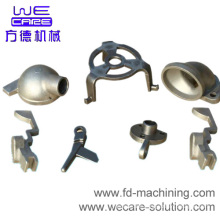

Model NO.: IC-106 Die Casting Method: Soluble Die Casting Machining: Machining Center Surface Preparation: Polishing Tolerance Grade: 8 Certification: SGS, ISO 9001:2008 Service: OEM and ODM Size: as Your Requirment Delivery Time: 30 Days After Receiving The Payment Trademark: wecare Origin: China Die Casting Machine Type: Cold Chamber Die Casting Machine Application: Machinery parts Material: Aluminum Alloy Pressure Chamber Structure: Vertical Casting Surface Quality Level: 3 Weight: Ranging From 0.01 Kg to 100kg Surface Ttreatment: Polishing, Anodising, Powder Coating etc Product Capacity: 1000000 PCS/Month Export Markets: Global Specification: ASTM, AISI, BS, JIS HS Code: 73259990 INVESTMENT CASTING / Sand Casting / Lost Wax Casting/PRECISION CASTING/GRAVITY CASTING/Stainless Steel Casting/carbon Steel Casting / die casting/Cookware Handle casting/pan handle casting/home hardware casting.

1, The investment casting include shell process (Colloidal Silica process) and the water glass process. A wide range of alloys is available for investment casting. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys.

2, Investment casting shell process can range from a weight of just a few ounces to approximately 100 pounds(45Kg). Water glass process of investment Castings may range in weight from several ounces to approximately 200 pounds(90Kg).

3, Surface treatment of investment casting parts: Heat treatment, machining, polishing, chrome/zinc/nickel plating, etc. A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

4, These parts are used in machine assembly, valve&pump parts, auto&Motorcycle Parts, train&railway parts, marine hardware, construction hardware, electrical, furniture, etc.

5, Investment casting parts weight: 0.2kg-500kg; Standard of investment casting parts: AISI, ASTM, DIN, GB, BS, JIS, NF, AAR; Quality system certificate for investment casting: ISO9001: 2000

Contact us if you need more details on Steel Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Parts、Lost Wax Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

1, The investment casting include shell process (Colloidal Silica process) and the water glass process. A wide range of alloys is available for investment casting. They include carbon steels, low alloy steels, stainless steels, tool steels and copper based alloys.

2, Investment casting shell process can range from a weight of just a few ounces to approximately 100 pounds(45Kg). Water glass process of investment Castings may range in weight from several ounces to approximately 200 pounds(90Kg).

3, Surface treatment of investment casting parts: Heat treatment, machining, polishing, chrome/zinc/nickel plating, etc. A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

4, These parts are used in machine assembly, valve&pump parts, auto&Motorcycle Parts, train&railway parts, marine hardware, construction hardware, electrical, furniture, etc.

5, Investment casting parts weight: 0.2kg-500kg; Standard of investment casting parts: AISI, ASTM, DIN, GB, BS, JIS, NF, AAR; Quality system certificate for investment casting: ISO9001: 2000

| Material available | Carbon steel, Stainless steel, spring steel, Bronze, brass, copper alloy, aluminum alloy, tinplate, nickel silver, plastic |

| Surface treatment available | Zinc/Nickel/Chrome Plating(color or natural), Galvanization, Anodizing, Hard Anodizing, Oil Spraying, Powder Coating, Polishing, Passivate, Brush, Wire drawing, etc. |

| Manufacturing Methods | Investment Casting, Die Casting, SAND CASTING , Stamping , CNC Machining, Forging , |

| Specification | OEM & make per customer' s drawing or sample |

| Package | According to customer' s requirement; |

| Tolerance | CNC Machining Parts: +/-0.002 |

| Service available | We supply pre-production samples for customer final confirmation before mass production; |

| Certificate | ISO9001: 2000 |

Product Categories : INVESTMENT CASTING

Premium Related Products

Other Products

Hot Products

High demand export products grey iron casting buy direct from china manufacturerOEM custom precision iron cast foundry top selling products in alibabaAlibaba supplier wholesales new forklift parts hot new products for 2016 usaChina supplier professional central machinery parts, machinery industrial parts toolssteel machinery partsOEM shell casting iron teethsteel forged tow hookDensen unnormalized OEM mini hydraulic pistonOEM high quality nonstandard sheet metal hot stamping partsOEM customized blind flangeNew Densen unnormalized OEM hydraulic cylinder tubestainless steel pipe fittingCustomized auto parts made in Chinastainless steel pipe fitting made in ChinaCustomized high quality cast steel parts made in Chinahammer union with thread for oilfield