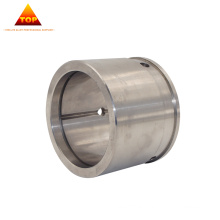

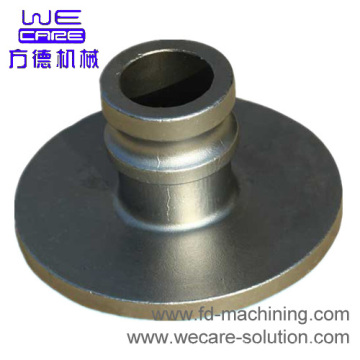

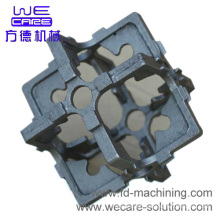

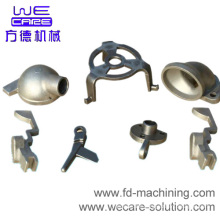

OEM Aluminum Gravity Die Casting

Basic Info

Model No.: GC-23

Product Description

Model NO.: GC-23 Machining: Boring Machine Surface Treatment: Spray Coating Casting Tolerance: +/-0.5mm Dimension Report: Dimension Report Certification: SGS, RoHS, ISO 9001:2000 Service: OEM and ODM Product Capacity: 1000000 PCS/Month Delivery Time: 30 Days After Receiving The Payment Specification: ISO, SGS Application: Hardware Material: Aluminum Alloy Design: 3D Material Inspection Report: Material Inspection Report Standard: BS Weight: Ranging From 0.01 Kg to 100kg Surface Ttreatment: Polishing, Anodising, Powder Coating etc Export Markets: Global Trademark: wecare Origin: China

Good Quality Gear House of GRAVITY CASTING in China With CE Certification

The die casting process provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical Castings can be produced in a very short time.

Die castings have a long service life because they are durable, dimensionally stable, and heat resistant.

Die cast parts are stronger than plastic injection molded parts having the same dimensions. Die castings can be produced with thinner wall sections that are not possible with Other casting methods.

Die castings can be smooth or textured and they are easily plated or painted with a minimum of surface preparation.

Die castings offer simplified assembly by providing integral fastening elements such as bosses and studs. Holes can be cored and made to tap drill sizes or external threads can be casted.

Permanent molding is desired by those requiring an Aluminum Casting with good density and superior mechanical properties. Castings made with this method are much more dimensionally accurate and repeatable than those made using sand methods. This reduces or eliminates much of the machining that may be required.

Advantages: Very repeatable, sound density, can utilize cores in the casting design, short lead times, excellent appearance, tight tolerances, perfect for high volume.

Contact us if you need more details on Gravity Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Lower Pressure Die Casting、Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Good Quality Gear House of GRAVITY CASTING in China With CE Certification

The die casting process provides complex shapes within closer tolerances than many other mass production processes. Little or no machining is required and thousands of identical Castings can be produced in a very short time.

Die castings have a long service life because they are durable, dimensionally stable, and heat resistant.

Die cast parts are stronger than plastic injection molded parts having the same dimensions. Die castings can be produced with thinner wall sections that are not possible with Other casting methods.

Die castings can be smooth or textured and they are easily plated or painted with a minimum of surface preparation.

Die castings offer simplified assembly by providing integral fastening elements such as bosses and studs. Holes can be cored and made to tap drill sizes or external threads can be casted.

Permanent molding is desired by those requiring an Aluminum Casting with good density and superior mechanical properties. Castings made with this method are much more dimensionally accurate and repeatable than those made using sand methods. This reduces or eliminates much of the machining that may be required.

Advantages: Very repeatable, sound density, can utilize cores in the casting design, short lead times, excellent appearance, tight tolerances, perfect for high volume.

| Process available | silica sol,sodium silicate (soluble glass) and compound process |

| Material available | Duplex stainless steel,stainless steel,carbon steel, Alloy Steel, and etc. |

| Standard | ASTM or as your requirement |

| Product | all kinds of casting(unit weight ≥0.1kg) |

| Surface finish | Passivation,polishing or as your request |

| Applied software | Pro/E, Auto CAD, Solid Work 2001,CAXA, UG, CAD/CAM/CAE |

| Production capacity | more than 2,000MT per year |

| heat treatment: | anneal, quenching, normalizing, carburizing,polishing, plating |

| Machining | CNC and NC machining, turning, milling, drilling, boring, threading, grinding machines and test facility |

| Certification | ObtainISO9001:2008Quality System Certified and CE/PED Certified by TUV |

Product Categories : GRAVITY CASTING

Premium Related Products

Other Products

Hot Products

High demand export products grey iron casting buy direct from china manufacturerOEM custom precision iron cast foundry top selling products in alibabaAlibaba supplier wholesales new forklift parts hot new products for 2016 usaChina supplier professional central machinery parts, machinery industrial parts toolssteel machinery partsOEM shell casting iron teethsteel forged tow hookDensen unnormalized OEM mini hydraulic pistonOEM high quality nonstandard sheet metal hot stamping partsOEM customized blind flangeNew Densen unnormalized OEM hydraulic cylinder tubestainless steel pipe fittingCustomized auto parts made in Chinastainless steel pipe fitting made in ChinaCustomized high quality cast steel parts made in Chinahammer union with thread for oilfield