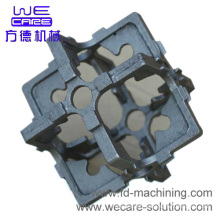

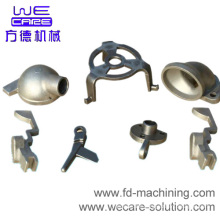

CNC Machining Parts for Spare Parts

Basic Info

Model No.: GC-16

Product Description

Model NO.: GC-16 Machining: Boring Machine Surface Treatment: Spray Coating Casting Tolerance: +/-0.5mm Dimension Report: Without Dimension Report Certification: SGS, CE Service: OEM and ODM Size: as Your Requirment Delivery Time: 30 Days After Receiving The Payment Trademark: wecare Origin: China Application: Hardware Material: Copper Alloy Design: 3D Material Inspection Report: Without Material Inspection Report Standard: BS Weight: Ranging From 0.01 Kg to 100kg Surface Ttreatment: Polishing, Anodising, Powder Coating etc Product Capacity: 1000000 PCS/Month Export Markets: Global Specification: ISO, SGS Machined parts character

1, Tight tolerance, Provide ODM/OEM service

2, ISO9001/2001, TS16949 approval, Strict quality control system

3, Small quantity accepted

4, Precision machining, CNC machining, milling, turning, drilling, grinding, Stamping, bending, Forging, planning, welding, laser cutting

5, Various material available(Carbon steel, Stainless steel, aluminium and aluminium alloy, Brass and Brass alloy, Plastic etc)

6, Usage: Auto & motorcycle, mining machinery, building industry, electrical and electronic products, industrial machinery and equipment and transportation. etc.

7, Standard: According to the dimension tolerance of machining of customers' requirement.

8, Surface roughness: Ra0.8-3.2

9, Weight: Ranging from 0.50g to 10000kg

10, Surface finish: Polishing, oiled (rust-prevented), zinc-plated, nickel-plated, chrome-plated, hot-galvanized, sandblasting, painting, powder-coating.

Machined parts production range:

We are a professional manufacturer of casting and machining. Most of our production is automobile parts, meter, instrument casing and other productions for civil and industry use according to concerned national standard. We have professional fixture and testing tools for many required production which can fit various machinofactures'capacity.

Workshop equipment of casting and machining:

Die casting machine: 7machines for weight 900tons to 63tons and 4 machines for machining center, 12 machines for CNC and other more than 40 normal machines. We have 1 equipment for three coordinates measuring and any other infiltrationh, shot blasting, washing and presssure testing equipments.

Casting and machining inspection:

Inspection: In-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: Hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

1. OEM/ODM/custom service is provided

2. High precision, tolerance can be ± 0.002mm

3. No MOQ

4. Fast lead time

5. DIN, JIS, ASTM, AISI, BS, GB standard

Contact us if you need more details on Aluminum GRAVITY CASTING. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Gravity Casting、ALUMINUM DIE CASTING. If these products fail to match your need, please contact us and we would like to provide relevant information.

1, Tight tolerance, Provide ODM/OEM service

2, ISO9001/2001, TS16949 approval, Strict quality control system

3, Small quantity accepted

4, Precision machining, CNC machining, milling, turning, drilling, grinding, Stamping, bending, Forging, planning, welding, laser cutting

5, Various material available(Carbon steel, Stainless steel, aluminium and aluminium alloy, Brass and Brass alloy, Plastic etc)

6, Usage: Auto & motorcycle, mining machinery, building industry, electrical and electronic products, industrial machinery and equipment and transportation. etc.

7, Standard: According to the dimension tolerance of machining of customers' requirement.

8, Surface roughness: Ra0.8-3.2

9, Weight: Ranging from 0.50g to 10000kg

10, Surface finish: Polishing, oiled (rust-prevented), zinc-plated, nickel-plated, chrome-plated, hot-galvanized, sandblasting, painting, powder-coating.

| Process available | silica sol,sodium silicate (soluble glass) and compound process |

| Material available | Duplex stainless steel,stainless steel,carbon steel, Alloy Steel, and etc. |

| Standard | ASTM or as your requirement |

| Product | all kinds of casting(unit weight ≥0.1kg) |

| Surface finish | Passivation,polishing or as your request |

| Applied software | Pro/E, Auto CAD, Solid Work 2001,CAXA, UG, CAD/CAM/CAE |

| Production capacity | more than 2,000MT per year |

| heat treatment: | anneal, quenching, normalizing, carburizing,polishing, plating |

| Machining | CNC and NC machining, turning, milling, drilling, boring, threading, grinding machines and test facility |

| Certification | ObtainISO9001:2008Quality System Certified and CE/PED Certified by TUV |

Machined parts production range:

We are a professional manufacturer of casting and machining. Most of our production is automobile parts, meter, instrument casing and other productions for civil and industry use according to concerned national standard. We have professional fixture and testing tools for many required production which can fit various machinofactures'capacity.

Workshop equipment of casting and machining:

Die casting machine: 7machines for weight 900tons to 63tons and 4 machines for machining center, 12 machines for CNC and other more than 40 normal machines. We have 1 equipment for three coordinates measuring and any other infiltrationh, shot blasting, washing and presssure testing equipments.

Casting and machining inspection:

Inspection: In-house and third party

All the products are strictly inspected by operator and skilled QC with record put down.

Universal inspection tools: Hardness tester, Height ruler, Depth ruler, Outside ruler, Venire Caliper, etc.

1. OEM/ODM/custom service is provided

2. High precision, tolerance can be ± 0.002mm

3. No MOQ

4. Fast lead time

5. DIN, JIS, ASTM, AISI, BS, GB standard

Contact us if you need more details on Aluminum GRAVITY CASTING. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Gravity Casting、ALUMINUM DIE CASTING. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : GRAVITY CASTING

Premium Related Products

Other Products

Hot Products

High demand export products grey iron casting buy direct from china manufacturerOEM custom precision iron cast foundry top selling products in alibabaAlibaba supplier wholesales new forklift parts hot new products for 2016 usaChina supplier professional central machinery parts, machinery industrial parts toolssteel machinery partsOEM shell casting iron teethsteel forged tow hookDensen unnormalized OEM mini hydraulic pistonOEM high quality nonstandard sheet metal hot stamping partsOEM customized blind flangeNew Densen unnormalized OEM hydraulic cylinder tubestainless steel pipe fittingCustomized auto parts made in Chinastainless steel pipe fitting made in ChinaCustomized high quality cast steel parts made in Chinahammer union with thread for oilfield