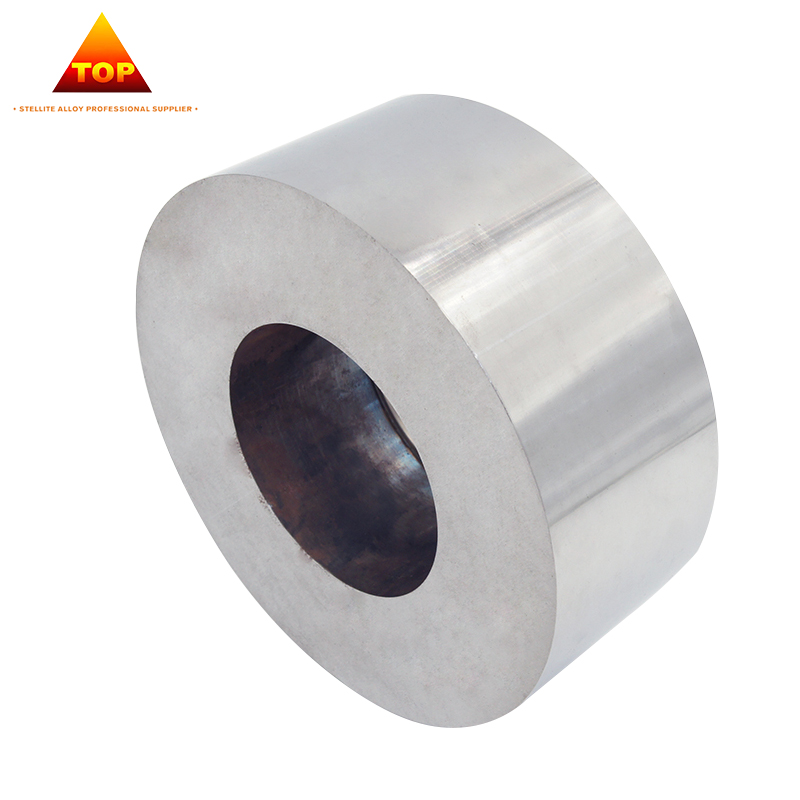

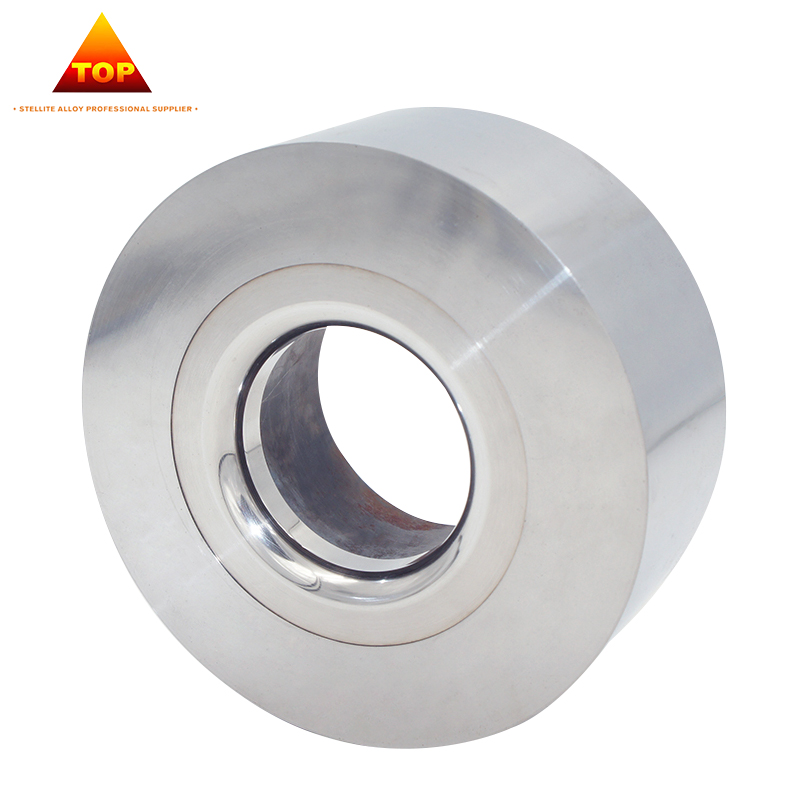

Stellite vs Tungsten Carbide Cobalt Alloy Extrusion Die Stellite 3 Extrusion Die Core

Product Description

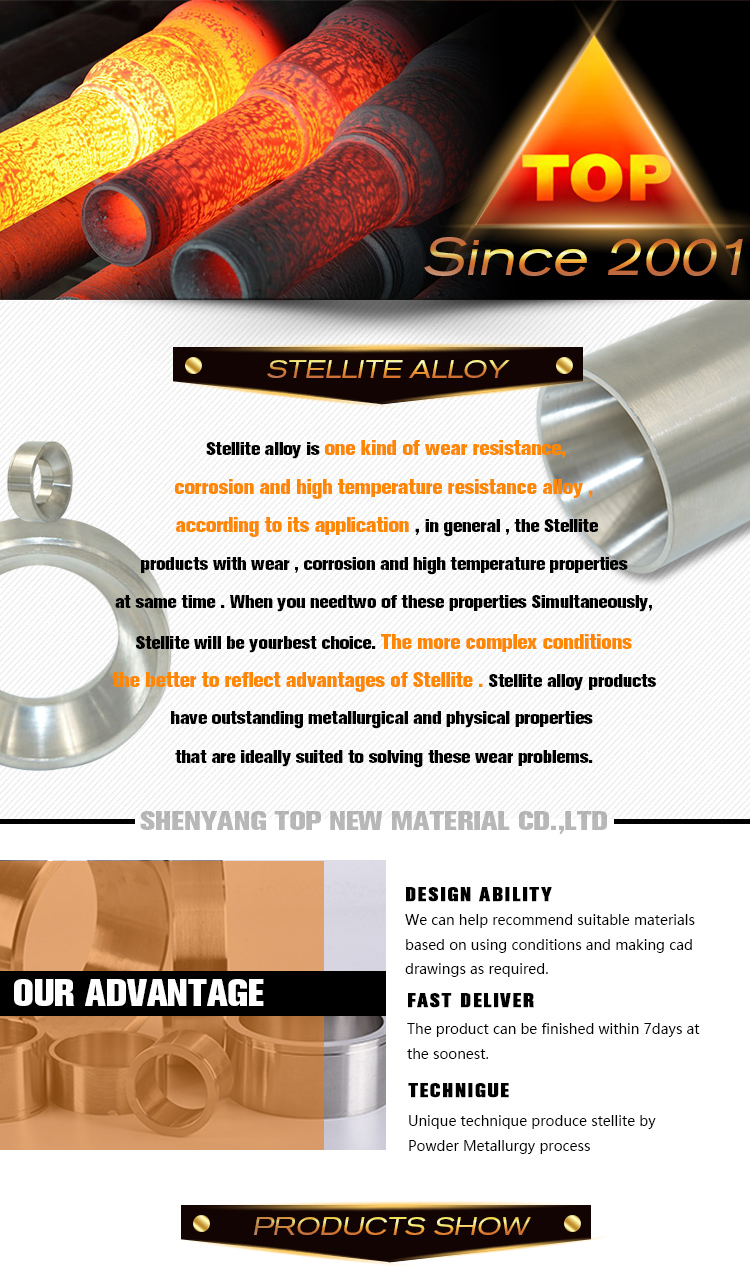

Powder Metallurgy Manufacturing Cobalt Alloy extrusion die Stellite 3 Extrusion Die Core

Powder Metallurgy Manufacturing Cobalt Alloy extrusion die Stellite 3 Extrusion Die Core

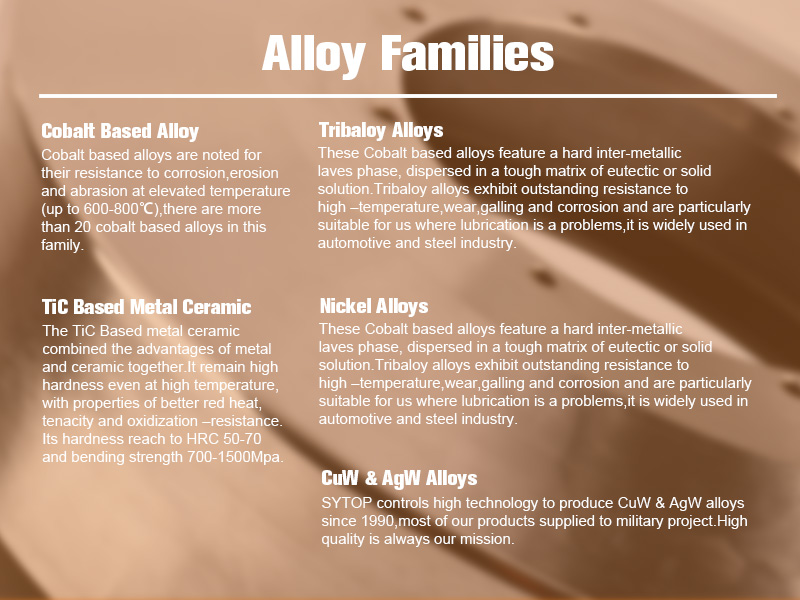

(1.)cobalt alloy is a range of cobalt-chromium alloys designed for wear resistance.

(2)It is a completely non-magnetic and corrosion , resistant cobalt alloy.

(3)There are a number of Stellite alloys, with various compositions optimised for different uses.

(4)Some are formulated to maximize combinations of wear resistance, corrosion resistance,

or ability to withstand extreme temperatures.

Chemical Composition

| Brand and No | Carbon | Manganese | Silicon | Chrom | Nickel | Moly | Tung | Cobalt | Iron | Other |

| cobalt based alloy3 | 2.00-2.70 | 1.00 | 1.00 | 29.0-33.0 | 3.00 | 11.0-14.0 | Bal. | 3.00 | P.03MAX S.03MAX | |

| cobalt based alloy4 | 1.00 | 1.00 | 1.5 | 28.0-32.0 | 3.00 | 1.50 | 12.5-15.5 | Bal. | 3.00 | |

| cobalt based alloy6 | 90-1.4 | 1.00 | 1.5 | 27.0-31.0 | 3.00 | 1.50 | 3.50-5.50 | Bal. | 3.00 | P.04MAX S.04MAX

|

Features

1. Heat Resistance, wear resistance, corrosion resistance

2. Made as required dimensions and materials

3. Main products: valve seat, pump parts, pistons, bushings, nozzles etc

Advantages

1. Excellent wear resistance , corrosion resistance and high temperature resistance

2. Easy to machine

Q1: Are you a manufacturer or a trading company?

A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience.

Q2: What's the material of your bushings/sleeves?

A2: It's the CoCrW alloy, which is usually called stellite alloy.

Q3: What's the stellite alloy?

A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat resistance and corrosion resistance.

Q4: What's the lead time of extrusion mould?

A4: 15-35 days depending on the order quantity.

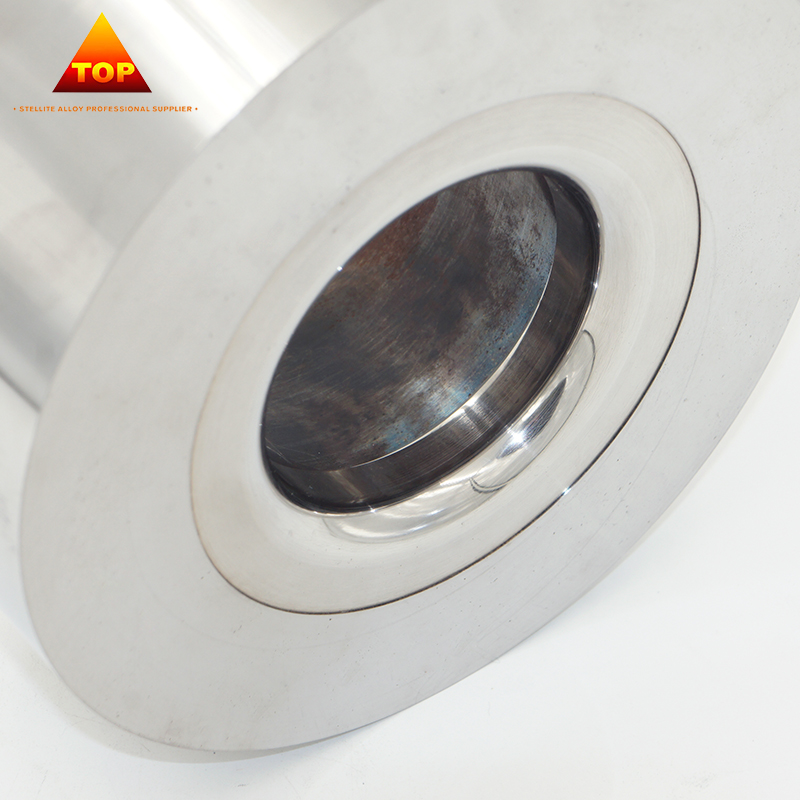

Q5: What's the tolerance and surface finish we can control?

A5: As your demand.

Q6: How do we deliver the seats?

A6: We are the VIP customer of DHL express with good discounts.

Q7: MOQ?

A7: 5pcs

Q8: Why I choose your company?

A8: We are professional. We are reliable. We are easy communication.

Your feedback is our best honor, please do not hesitate to give us your valuable feedback. Send your inquiry details in the below for free sample , Click "Send" Now !

Product Categories : extrusion die > Cold stamping die

Premium Related Products