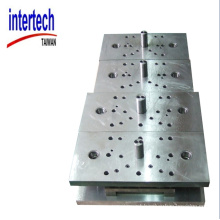

Customized Punching Mould Cutting Die Tic cermet Cold Heading Dies

Product Description

Customized Punching Die Cutting Mould Tic cermet Cold Heading Dies

Customized Punching Die Cutting Mould Tic cermet Cold Heading Dies

Tic cermet tensile die material, when stretched stamped stainless steel, the service life is more than 4 times that of Kennametal CD750 cemented carbide

Our newly developed TiC base's metal ceramics possess comprehensive properties that can be applied to copper extrusion die and sealing Spare Parts where ware-resistance and corrosion resistance are required. It can remains high hardness even at red heat, better tenacity and oxidization-resistance. Density is 5.6~6.9g/cm3, hardness is HRC50~70 and bending strength is 700-2000MPa. The properties of wear-resistance are over six times more than the steel ones (3Cr2W8V).

Physical Properties

| Brand and NO. | Density (g/cm3)≥ | Hardness HRC≥ | Remarks | Bending Strength Mpa≥ |

| TP30 | 6.54 | 50 |

|

|

| TP35 | 6.29 | 53 | (Metal Ceramics) | 700 |

| TP40 | 6.17 | 55 | (Metal Ceramics With Steel Attachment) | 2000 |

| TP45 | 6.05 | 59 |

|

|

| TP50 | 5.85 | 63 |

|

Q1: Are you a manufacturer or a trading company?

A1: We are the manufacturer located in the north of China with 15 years producing experience and 10 years exporting experience.

Q2: What's the material of your bushings/sleeves?

A2: It's the CoCrW alloy, which is usually called stellite alloy.

Q3: What's the stellite alloy?

A3: It is a range of cobalt-chromium alloys designed for wear resistance, heat resistance and corrosion resistance.

Q4: What's the lead time of extrusion mould?

A4: 15-35 days depending on the order quantity.

Q5: What's the tolerance and surface finish we can control?

A5: As your demand.

Q6: How do we deliver the seats?

A6: We are the VIP customer of DHL express with good discounts.

Q7: MOQ?

A7: 5pcs

Q8: Why I choose your company?

A8: We are professional. We are reliable. We are easy communication.

Your feedback is our best honor, please do not hesitate to give us your valuable feedback. Send your inquiry details in the below for free sample , Click "Send" Now !

Product Categories : extrusion die > Cold stamping die

Premium Related Products