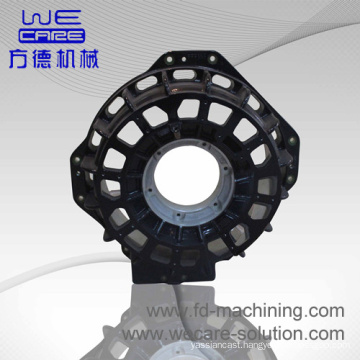

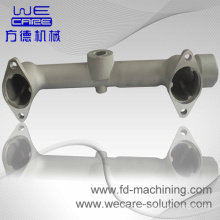

Handwheel Part for Valve Body Sand Casting

Basic Info

Model No.: CNC-36

Product Description

Model NO.: CNC-36 Casting Form Material: Metal Casting Form Usage Count: Permanent Surface Roughness: Ra12.5 Machining Tolerance: +/-0.01mm Certification: SGS, RoHS, ISO 9001:2000 Size: as Your Requirment Surface Ttreatment: Polishing, Anodising, Powder Coating etc Delivery Time: 30 Days After Receiving The Payment Trademark: Wecare Specification: IOS, SGS, CE Casting Method: Special Casting Casting Metal: Nonferrous Alloys Surface Treatment: Electroplating Coating: Syrup or pulp waste Standard: AISI Service: OEM and ODM Weight: Ranging From 0.01 Kg to 100kg Product Capacity: 1000000 PCS/Month Export Markets: Global Transport Package: Carton, Then Put Into The Plywood Box or Pallet Origin: China

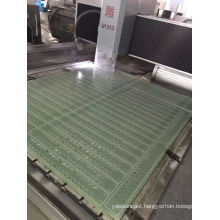

Precision Machined Part For Machining Lighting Parts Heat sink With Rohs

Our aluminum heat sink is used to absorb thermal energy or heat from another object through thermal compounds which are also known as thermally conductive materials. At a relatively high temperature, the heat is absorbed from the object and transferred to the heat sink which has a much larger heat capacity. Being a practical thermal energy solution for both low and high volumes, extruded aluminum heat sink is widely applied for heat radiation of refrigerators, engines, medical devices, lasers, CPUs, etc. These applications are quite

Helpful in such industries as Electronics, medical equipment, industrial manufacturing, household appliance, LED lighting, and military industry, etc. Usually, aluminum heat sink is designed with different lengths, noise levels, Speeds, widths, styles, height and weight, and the extruded heat sink is Typically made of aluminum alloys as 6061 and 6063. The most popular extruded Aluminum heat sink is designed with a flat aluminum base with vertical radiating Fins for increased surface area, thus providing better heat dissipation Performance. Extruded aluminum heat sink can both be passive and active. Active heat sink

Uses power sources such as integrated fans with directed fins and the surface Area of the aluminum heat sink can be increased by directing airflow patterns Through the fins. Passive one does not use any mechanical components and the Heat can be dissipated through convection or transferred through liquid or gas Caused by molecular motion.

Contact us if you need more details on Aluminum Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Part、Aluminum Alloy Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Aluminum Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Part、Aluminum Alloy Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Precision Machined Part For Machining Lighting Parts Heat sink With Rohs

Our aluminum heat sink is used to absorb thermal energy or heat from another object through thermal compounds which are also known as thermally conductive materials. At a relatively high temperature, the heat is absorbed from the object and transferred to the heat sink which has a much larger heat capacity. Being a practical thermal energy solution for both low and high volumes, extruded aluminum heat sink is widely applied for heat radiation of refrigerators, engines, medical devices, lasers, CPUs, etc. These applications are quite

Helpful in such industries as Electronics, medical equipment, industrial manufacturing, household appliance, LED lighting, and military industry, etc. Usually, aluminum heat sink is designed with different lengths, noise levels, Speeds, widths, styles, height and weight, and the extruded heat sink is Typically made of aluminum alloys as 6061 and 6063. The most popular extruded Aluminum heat sink is designed with a flat aluminum base with vertical radiating Fins for increased surface area, thus providing better heat dissipation Performance. Extruded aluminum heat sink can both be passive and active. Active heat sink

Uses power sources such as integrated fans with directed fins and the surface Area of the aluminum heat sink can be increased by directing airflow patterns Through the fins. Passive one does not use any mechanical components and the Heat can be dissipated through convection or transferred through liquid or gas Caused by molecular motion.

| Description | Aluminum industrial extrusion profile | SGS TEST APPROVAL |

| Alloy/Temper | 6061-T6/6063-T6; 6082-T6/6351-T6; 7075/7005-T6 | SGS TEST APPROVAL |

| Surface treatment | Mill finishes;Anodized; Powder coated;Wooden grain, Machine/Acid polished and etc | SGS TEST APPROVAL |

| Standard apply | EN755;DIN;ASTMB221;GB5237-2008 and etc. | SGS TEST APPROVAL |

| Price | SMM/LME Primary aluminum price + the most competitive conversion cost | SGS TEST APPROVAL |

| Mould policy | Each item purchased volume get to 3tons , refund mould payment | SGS TEST APPROVAL |

| Delivery timetable | sample: within 20 days; order: within 20 days | SGS TEST APPROVAL |

| Guarantee term | If the shipped products can not meet required, the total order amount will be refund back without delay, or arrange new replacement cargoes instead. | SGS TEST APPROVAL |

Contact us if you need more details on Aluminum Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Part、Aluminum Alloy Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Aluminum Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Casting Part、Aluminum Alloy Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : CNC MACHINED PART

Premium Related Products

Other Products

Hot Products

High demand export products grey iron casting buy direct from china manufacturerOEM custom precision iron cast foundry top selling products in alibabaAlibaba supplier wholesales new forklift parts hot new products for 2016 usaChina supplier professional central machinery parts, machinery industrial parts toolssteel machinery partsOEM shell casting iron teethsteel forged tow hookDensen unnormalized OEM mini hydraulic pistonOEM high quality nonstandard sheet metal hot stamping partsOEM customized blind flangeNew Densen unnormalized OEM hydraulic cylinder tubestainless steel pipe fittingCustomized auto parts made in Chinastainless steel pipe fitting made in ChinaCustomized high quality cast steel parts made in Chinahammer union with thread for oilfield