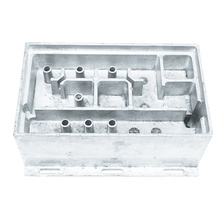

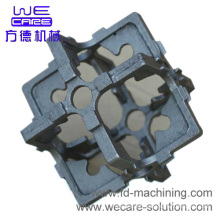

Customized Aluminum Alloy Die Casting of Motorcycle Engine Housing

Basic Info

Model No.: ADC011

Product Description

Model NO.: ADC011 Die Casting Method: Soluble Die Casting Machining: CNC Machining Surface Preparation: Polishing Tolerance Grade: 4 Certification: SGS, ISO 9001:2008 Surface Ttreatment: Polishing, Anodising, Powder Coating etc Weight: Ranging From 0.01 Kg to 100kg Export Markets: Global Specification: ISO, SGS Die Casting Machine Type: Cold Chamber Die Casting Machine Application: Machinery parts Material: Aluminum Pressure Chamber Structure: Vertical Casting Surface Quality Level: 1 Service: OEM and ODM Product Capacity: 1000000 PCS/Month Delivery Time: 30 Days After Receiving The Payment Trademark: wecare Origin: China There are 10 sets of zinc die casting machines specialized in manufacture of zinc die casting components widely used for automobile industry, furniture, electricity industry like oven components, zinc die casting handle, car license plate frame, etc. We can provide secondary precision CNC machining, drilling, tap thread if customer required. And surface finishing always applied for zinc die casting parts like polishing, powder coating, brass coating, chrome plating, Nickel plating, or variation in barrel(tumbling) to make the part shiny and smooth.

Comparison to ALUMINUM DIE CASTING technology, zinc die casting parts with better mechanical properties like tensile, resistance and easy applied for surface finishing variation.

Detailed Product Description

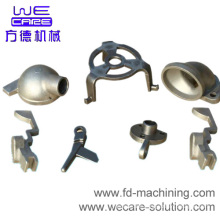

High Precision Custom Made Aluminum Die Casting CNC Machining Parts (ADC-011)

Description:

1. Process of aluminum die Casting Part: Die casting + complete machining + heat treatment + surface treatment

2. Aluminum die casting mold Material: 8407, H13, P20, etc. Aluminum die casting mold Life: >1, 000, 000 times, Aluminum die casting mold Design: According to Drawing or Sample.

3. Aluminum die casting accessory material: Aluminum Alloy A380 or as customer's requirement.

Aluminum Die casting is especially suited to production of large quantities of relatively small parts. The more important reasons for using light Metal Casting are low weight, mechanical strength, stiffness and electrical properties. Other applications are e. G. Components for the power transmission line in the vehicle industry and Electronics industry.

Specifications:

Contact us if you need more details on Pressure Die Casting. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Motorcycle Engine Part、Metal Die Casting. If these products fail to match your need, please contact us and we would like to provide relevant information.

Comparison to ALUMINUM DIE CASTING technology, zinc die casting parts with better mechanical properties like tensile, resistance and easy applied for surface finishing variation.

Detailed Product Description

High Precision Custom Made Aluminum Die Casting CNC Machining Parts (ADC-011)

Description:

1. Process of aluminum die Casting Part: Die casting + complete machining + heat treatment + surface treatment

2. Aluminum die casting mold Material: 8407, H13, P20, etc. Aluminum die casting mold Life: >1, 000, 000 times, Aluminum die casting mold Design: According to Drawing or Sample.

3. Aluminum die casting accessory material: Aluminum Alloy A380 or as customer's requirement.

Aluminum Die casting is especially suited to production of large quantities of relatively small parts. The more important reasons for using light Metal Casting are low weight, mechanical strength, stiffness and electrical properties. Other applications are e. G. Components for the power transmission line in the vehicle industry and Electronics industry.

Specifications:

| Item | Description | The contents |

| Die casting parts | Model | ADC-02 |

| Molding technics | Die casting | |

| Material | A380 | |

| Dimension | ||

| The weight | ||

| Surface treatment | electroplate | |

| Die casting moulds | Cavity | Single |

| Material | SKD61 | |

| Heat treatment | Hardened | |

| Hardness | HRC50~55 | |

| Mould feature | Advanced design, Novel structure, High precision, Quality materials, Long lifetime, Short delivery time | |

| Equipments | CNC precision mould engraving machine, CNC forming machine CNC turning, EDM, Linear cutting machine, Die spotting machine(200T), Die casting machine(150T~2000T), Lathe, Grinding machine; CMM, Material detector, Hardness test device, spectrograph, etc | |

| Software | CAD, UG, Pro/E, JSCAST-v8, Solidworks etc. | |

| Quality certification | SGS. ISO9001-2000 | |

Product Categories : ALUMINUM DIE CASTING

Premium Related Products

Other Products

Hot Products

High demand export products grey iron casting buy direct from china manufacturerOEM custom precision iron cast foundry top selling products in alibabaAlibaba supplier wholesales new forklift parts hot new products for 2016 usaChina supplier professional central machinery parts, machinery industrial parts toolssteel machinery partsOEM shell casting iron teethsteel forged tow hookDensen unnormalized OEM mini hydraulic pistonOEM high quality nonstandard sheet metal hot stamping partsOEM customized blind flangeNew Densen unnormalized OEM hydraulic cylinder tubestainless steel pipe fittingCustomized auto parts made in Chinastainless steel pipe fitting made in ChinaCustomized high quality cast steel parts made in Chinahammer union with thread for oilfield